Screw And Bolt Guide

A screw by definition is not a bolt. A bolt passes through a hole of a larger diameter than its thread and is held in place by a nut or similar device. It is not designed to be turned. A screw is a shaft with a helical groove. The thread essentially mates with the helix in the material it is turned through. The screw may be used with a part that has a mating helix already placed in the material (called a tapped hole) or may be a self tapping screw which creates the helix as it is turned in the material.

The glossary below gives you the basic information on various types screws and bolts:

-

A hex cap screw has a protruding hexagonal head, designed to be driven by a spanner or wrench.

-

A socket cap screw has a hexagonal recessed drive, usually with a cylindrical head, but can also be found with a rounded button head or a countersunk flat head.

-

Wood and chipboard screws have a tapered shaft. A hole of about the diameter of the shaft, but less than the diameter of the thread, is often drilled into the wood; screws can be driven into undrilled wood, but there is a risk of splitting the workpiece. Chipboard is less likely to split. A hole can be drilled in brick, concrete, or other hard materials, and a wall plug inserted; a woodscrew can then be driven into the plug.

-

Lag screw, lag bolt or coach screw refers to a large wood screw with a head, square or hexagonal, driven by a wrench rather than a screwdriver.

-

A Machine screw has a cylindrical shaft, threaded its entire length, and fits into a nut or a tapped hole.

-

Self-tapping screws or thread cutting screws have sharp threads that cut into a material such as sheet metal or plastic. They are sometimes notched at the tip to aid in chip removal during thread cutting.

-

A Self-drilling screw is similar to a self-tapping screw, but has a drill-shaped point to cut through the material without prior drilling.

-

Thread rolling screws have a lobed (usually triangular) cross section. They form threads by pushing outward during installation. They may have tapping threads or machine threads.

-

A Drywall screw is a specialized self-tapping screw designed to bind drywall to wood or metal studs, but it has proven to be a versatile construction fastener.

-

A Set screw, used to prevent loosening due to vibration, is available with thumb screw, square head, Hex head (inset socket) and, most commonly, headless (a grub screw in UK parlance, designed to be inserted flush with or below the surface of the work piece). Alternatively defined to be a screw whose thread reaches the head (if any), as opposed to a bolt.

-

Dowel screw is a wood screw with two pointed ends and no head, used for making hidden joints between two pieces of wood.

-

A stud is similar to a bolt but without the head. Studs are threaded on both ends. In some cases the entire length of the stud is threaded, while in other cases there will be an unthreaded section in the middle. It may be anchored in concrete, for example, with only the threads on one end exposed. (See also: screw anchor, wedge anchor.)

-

An Eye bolt used for attaching cables to a surface.

-

A carriage bolt or coach bolt has a domed or countersunk head, and the shaft is topped by a short square section under the head. The rib neck carriage bolt has several longitudinal ribs instead of the square section, to grip into a metal part being fixed.

Machine Screw Sizing

Machine screws are described as 0-80, 2-56, 3-48, 4-40, 5-40, 6-32, 8-32, 10-32, 10-24, etc. up to size 16. The first number can be translated to a diameter, the second is the number of threads per inch. There is a coarse thread and a fine thread for each size, the fine thread being preferred in thin materials or when its slightly greater strength is desired.

The numbering system follows a roughly logarithmic series where an increase in each screw number size approximately doubles the tensile strength of the screw and is given by Dia = (#N X .013") + .060" Using this formula a #5 screw has a major diameter of .125" (1/8"), a #10 screw has a diameter of .190" (or 3/16" in practical terms), etc.

The formula applies for screw thread numbers #0 and higher, but does NOT apply to smaller Unified miniature screw thread series.Typically screws smaller than size #0 are supplied in the Unified Miniature Series. The formula for number sizes smaller than size #0 is given by Dia = .060" - (#zerosize X .013). So a #00 screw is .047" dia, #000 is .034" dia, etc.

The number series of machine screws once included odd numbers (7, 9, etc.) and extended up to #16 or more. Standardization efforts in the late 19th and the early part of the 20th century reduced the range of sizes considerably.

Now, it is less common to see machine screws larger than #14, or odd number sizes other than #1, #3 and #5. Even though #14 and #16 screws are still available, they are not as common as sizes #0 thru #12.

Sizes 1/4" diameter and larger are designated as 1/4"-20, 1/4"-28, etc. the first number giving the diameter in inches and the second number being threads per inch. Most thread sizes are available in UNC or UC (Unified Coarse Thread, example 1/4"-20) or UNF (example 1/4"-28 UNF or UF).

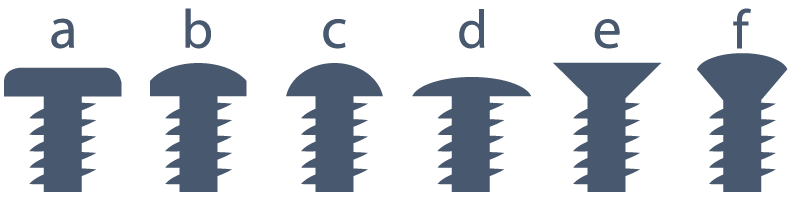

Screw Head Shapes

-

(a) pan head: a low disc with chamfered outer edge.

-

(b) button or dome head: cylindrical with a rounded top.

-

(c) round head: dome-shaped, commonly used for machine screws.

-

(d)truss head: lower-profile dome designed to prevent tampering.

-

(e) flat head or countersunk: conical, with flat outer face and tapering inner face allowing it to sink into the material.

-

(f)oval or raised head: countersunk with a rounded top.

-

bugle head: similar to countersunk, but there is a smooth progression from the shaft to the angle of the head, similar to the bell of a bugle.

-

cheese head: disc with cylindrical outer edge, height approximately half the head diameter.

-

fillister head: cylindrical, but with a slightly convex top surface.

-

socket head: cylindrical, relatively high, with different types of sockets (hex, square, torx, etc.).

-

mirror screw head: countersunk head with a tapped hole to receive a separate screw-in chrome-plated cover, used for attaching mirrors.

-

headless (set or grub screw): has either a socket or slot in one end for driving.